- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2025-10-28 Origin: Site

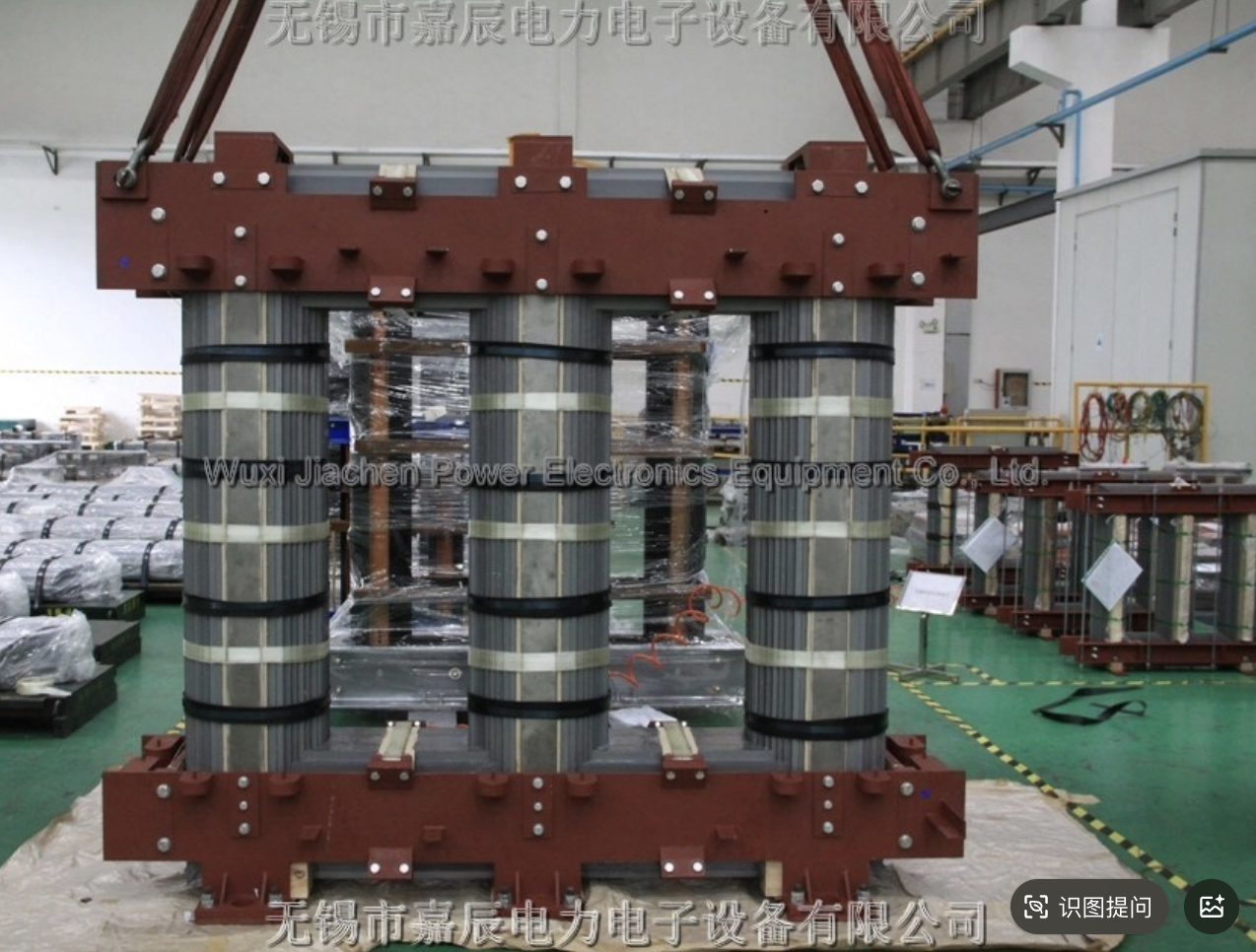

Transformers are essential in power distribution and industrial applications, and their efficiency largely depends on the design of the transformer core . Step lap construction is a widely used technique to reduce energy losses, improve voltage regulation, and minimize operational noise. By carefully stacking laminations in overlapping patterns, transformer manufacturers can optimize magnetic flux distribution and mechanical stability. Wuxi Jiachen Power Electronics Equipment Co., Ltd. produces high-quality transformer cores engineered for industrial transformers, motors, and rotors. Their products ensure low loss, high efficiency, and reliable long-term performance, making them suitable for demanding electrical systems. This article explores the design, advantages, key features, and applications of step lap stacked cores, helping engineers and buyers understand why this construction method is crucial for high-performance transformers.

A transformer core is the central part of a transformer that channels magnetic flux between the primary and secondary windings. The core’s material, geometry, and construction directly affect energy efficiency, noise, and operational stability. In step lap construction, the core is made by stacking laminations in an overlapping sequence, creating “steps” along the edges. This method reduces magnetic gaps and ensures smoother flux distribution, which minimizes eddy current losses and mechanical vibrations. Cold Rolled Grain Oriented (CRGO) steel is commonly used in high-efficiency cores due to its low hysteresis and high permeability in the rolling direction. Non-Oriented Silicon steel is also used for general-purpose transformers where multi-directional flux occurs. Proper stacking alignment and precise lamination placement are critical to achieving low-loss performance. Step lap cores are preferred in industrial and high-voltage transformers because they combine durability, efficiency, and noise reduction, making them an optimal choice for modern electrical systems.

Choosing the right transformer core is essential to optimize energy efficiency, reduce operating costs, and extend transformer lifespan. Step lap construction offers significant advantages over traditional straight-lap cores. By overlapping laminations, step lap cores reduce magnetic reluctance and eddy current losses, improving overall transformer efficiency. This design also reduces vibration and operational noise, which is particularly important for residential, commercial, and industrial environments. The right material selection, such as Cold Rolled Grain Oriented steel for high-performance transformers or Non-Oriented Silicon for multi-directional flux applications, ensures that the core meets specific operational requirements. Wuxi Jiachen Power Electronics Equipment Co., Ltd. provides transformer cores designed to achieve optimal efficiency, thermal performance, and durability. Selecting a step lap stacked core ensures smoother voltage regulation, lower losses, and reliable performance under heavy-duty or continuous operation.

Step lap construction is the defining feature of high-performance transformer cores. By overlapping the edges of laminations, this method minimizes flux leakage and reduces energy losses. It also distributes magnetic flux evenly across the core, which improves voltage regulation and reduces heating. Step lap cores provide mechanical stability, lower vibration, and reduced operational noise compared to conventional straight-lap cores. Properly stacked laminations with correct overlap length and thickness ensure maximum efficiency and long-term reliability. This construction method is widely used in industrial transformers, high-voltage applications, and renewable energy systems to achieve consistent performance and lower operating costs.

The choice of material is another critical feature. Cold Rolled Grain Oriented steel is ideal for step lap cores due to its high magnetic permeability and low hysteresis losses. Non-Oriented Silicon steel allows flexibility for applications requiring multi-directional flux, such as motors and rotors. Material thickness, surface insulation, and lamination quality directly affect energy efficiency and thermal management. Wuxi Jiachen Power Electronics Equipment Co., Ltd. carefully selects and processes materials to meet precise industrial standards, ensuring that transformer cores deliver reliable performance under varying operational conditions.

Material Type | Permeability | Core Loss (W/kg) | Application Use |

Cold Rolled Grain Oriented | High | Low | High-efficiency transformers |

Non-Oriented Silicon | Medium | Medium | Motors, general-purpose cores |

Standard Silicon Steel | Low | High | Basic transformers |

This table illustrates the key differences between materials used in step lap cores. Choosing the right material affects efficiency, thermal performance, and operational reliability.

Step lap stacked cores are used extensively in transformers, rotors, and motors. In transformers, they improve energy efficiency, reduce operational noise, and provide better voltage regulation. High-voltage distribution transformers, industrial power transformers, and renewable energy transformers all benefit from step lap construction. In motors, stacked cores enhance torque performance and magnetic flux distribution while reducing heat generation and vibration. Rotors and stators made with step lap cores exhibit higher reliability and efficiency in continuous or heavy-duty operations. Customized core designs from Wuxi Jiachen Power Electronics Equipment Co., Ltd. cater to these diverse applications, delivering energy-efficient solutions for both industrial and commercial environments.

Selecting the right transformer core requires careful consideration of several factors. First, the material should match the transformer’s operational requirements. High-efficiency transformers benefit from Cold Rolled Grain Oriented steel, while multi-directional flux applications may require Non-Oriented Silicon steel. Lamination thickness, stacking sequence, and insulation are crucial for minimizing eddy current losses and improving thermal performance. Designers must also consider mechanical stability, vibration control, and operational noise requirements. Step lap cores should be chosen when energy efficiency, low noise, and long-term reliability are priorities.

Core Type | Efficiency (%) | Noise Level (dB) | Application |

Step Lap Core | 98–99 | Low | Industrial & high-voltage transformers |

Straight Lap Core | 95–97 | Medium | General-purpose transformers |

Basic Stacked Core | 90–94 | High | Low-cost applications |

This comparison highlights the superior performance of step lap cores in efficiency and noise reduction, supporting their selection for high-demand industrial environments. Wuxi Jiachen Power Electronics Equipment Co., Ltd. provides detailed guidance and product options to help engineers select cores optimized for specific applications.

Step lap stacked cores significantly enhance transformer efficiency, reduce losses, and improve operational stability. By carefully selecting materials, optimizing lamination thickness, and precisely constructing the core, engineers can achieve superior performance for transformers, motors, and rotors. Wuxi Jiachen Power Electronics Equipment Co., Ltd. provides high-quality transformer cores designed to meet industrial standards and operational demands. Their products offer energy-efficient, low-noise, and durable solutions suitable for a wide range of transformer and motor applications. Explore their offerings to enhance performance, reliability, and efficiency in your electrical systems.

A: A transformer core is the magnetic structure inside a transformer that directs magnetic flux between primary and secondary windings. It improves voltage transformation efficiency, reduces energy losses, and ensures stable operation in industrial and high-voltage applications.

A: A wound core transformer is built from laminated steel sheets arranged around a central magnetic core, with primary and secondary windings precisely placed. This design offers high voltage insulation, accurate voltage transformation, and reduced stray losses. It is ideal for high-precision applications and heavy-duty electrical systems.

A: Toroidal core transformers are compact, lightweight, and produce minimal electromagnetic interference. Their circular shape ensures smooth magnetic flux distribution, resulting in quieter operation and improved efficiency. They are particularly suitable for noise-sensitive environments and space-constrained installations.

A: Wound cores provide exceptional accuracy, stability, and low magnetic leakage. This makes them ideal for industrial meters, energy monitoring systems, and high-voltage measurement applications where precise readings and reliable long-term performance are critical.