- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2025-10-28 Origin: Site

Imagine a world where electrical devices are inefficient and wasteful. Silicon steel revolutionizes electrical engineering, enhancing efficiency and performance. This article explores silicon steel's vital role in electrical engineering. You'll learn about its unique properties, applications in transformers, motors, and generators, and its future potential. Discover how silicon steel shapes the future of electrical technology.

Silicon steel , often called electrical steel, is a special type of steel designed for electrical applications. It mainly consists of iron combined with silicon, usually between 1% and 4.5%. The silicon content is key, as it improves the steel’s magnetic properties. This makes silicon steel essential in devices that rely on magnetic fields.

The addition of silicon reduces the steel’s electrical losses by increasing its electrical resistivity. This helps minimize energy wasted as heat when alternating currents flow through magnetic cores. Besides silicon and iron, small amounts of other elements like carbon, manganese, and aluminum may be present to enhance specific properties.

Silicon steel comes in two main types: grain-oriented and non-oriented. Each type suits different electrical engineering needs.

Grain-Oriented Silicon Steel (GOSS):**This type has its crystal grains aligned in one direction. The alignment enhances magnetic properties along that direction, making it ideal for transformer cores where magnetic flux flows mainly in one direction. GOSS reduces core losses and improves efficiency in transformers.

Non-Oriented Silicon Steel (NO):**Here, the grains are randomly oriented. This uniformity allows the steel to perform well in rotating machines like motors and generators, where magnetic fields change direction constantly. NO silicon steel balances magnetic performance in all directions.

Each type can be further processed into various thicknesses and coatings to suit specific applications. Thinner sheets reduce eddy current losses, while coatings provide electrical insulation between layers.

Note: Selecting the right silicon steel type depends on the device's magnetic flux pattern; grain-oriented suits transformers, non-oriented fits rotating machines.

Silicon steel is prized mainly for its excellent magnetic properties. It has high magnetic permeability, meaning it can easily become magnetized and support magnetic flux. This allows it to efficiently channel magnetic fields in electrical devices like transformers and motors. Additionally, silicon steel exhibits low core loss, which refers to the energy lost as heat during magnetization cycles. This low loss is crucial for energy-efficient electrical equipment, especially under alternating current (AC) conditions.

The grain-oriented type of silicon steel further improves magnetic properties by aligning its crystal grains. This alignment reduces magnetic hysteresis loss and eddy current loss along the grain direction, making it ideal for transformer cores where magnetic flux flows mostly in one direction. Non-oriented silicon steel, meanwhile, offers balanced magnetic performance in all directions, suitable for rotating machines.

Adding silicon to steel increases its electrical resistivity. Higher resistivity reduces eddy currents—loops of electric current induced within the metal by changing magnetic fields. Eddy currents cause unwanted energy loss and heating. By limiting these currents, silicon steel minimizes energy wastage and improves overall efficiency.

Moreover, silicon steel sheets are often coated with insulating layers. These coatings prevent electrical contact between stacked laminations, further reducing eddy current losses. The thickness of the steel laminations also affects electrical performance; thinner sheets mean less eddy current generation, enhancing efficiency in high-frequency applications.

Silicon steel maintains good mechanical strength and flexibility despite the addition of silicon. The silicon content hardens the steel, improving its wear resistance and durability. However, too much silicon can make the steel brittle, so the content is carefully controlled.

The steel's mechanical properties also depend on its processing. Annealing and cold rolling help achieve the desired balance between strength and ductility. Grain-oriented silicon steel requires precise heat treatment to develop its magnetic texture without compromising mechanical integrity.

In practical terms, silicon steel laminations can be easily stamped or cut into shapes needed for electrical machines without cracking. This workability combined with durability ensures long service life even in demanding environments.

Note: The magnetic, electrical, and mechanical properties of silicon steel are interrelated and must be optimized together to maximize performance in electrical engineering applications.

Silicon steel plays a crucial role in many electrical engineering devices due to its unique magnetic and electrical properties. Its ability to efficiently conduct magnetic flux while minimizing energy losses makes it the material of choice in key applications such as transformers, motors, and generators.

Transformers rely heavily on silicon steel, especially the grain-oriented type, to create efficient magnetic cores. In transformers, alternating current flows through coils, generating magnetic fields that transfer energy between circuits. The grain-oriented silicon steel’s aligned crystal structure allows magnetic flux to flow smoothly along one direction, reducing core losses like hysteresis and eddy currents.

Using silicon steel in transformer cores helps:

Increase energy efficiency by minimizing heat losses

Reduce size and weight of transformers due to better magnetic performance

Enhance reliability and longevity of transformer units

Transformers in power distribution networks and electrical equipment benefit greatly from the tailored magnetic properties of silicon steel laminations.

Electric motors, which convert electrical energy into mechanical motion, use non-oriented silicon steel in their stator and rotor cores. Since motors involve rotating magnetic fields, the magnetic flux changes direction continuously. Non-oriented silicon steel, with its randomly aligned grains, provides uniform magnetic properties in all directions, ensuring smooth motor operation.

This type of silicon steel helps motors by:

Reducing core losses during rotation

Improving torque and efficiency

Lowering operational noise and vibration

Motors in industrial machinery, household appliances, and electric vehicles all depend on high-quality silicon steel to achieve optimal performance.

Generators, which convert mechanical energy back into electrical energy, also utilize silicon steel cores. Like motors, they experience rotating magnetic fields, so non-oriented silicon steel is preferred. The steel’s high magnetic permeability allows efficient magnetic flux generation, while its high electrical resistivity limits eddy current losses.

Benefits of silicon steel in generators include:

Enhanced electrical output efficiency

Reduced heat generation and energy waste

Increased durability under continuous operation

Power plants and renewable energy systems use generators with silicon steel cores to maintain stable and efficient electricity production.

Tip: When selecting silicon steel for electrical devices, match grain-oriented steel to transformers and non-oriented steel to rotating machines for best magnetic performance and energy efficiency.

Silicon steel offers several key benefits that make it indispensable in electrical engineering. Its unique combination of properties improves the performance, cost, and durability of electrical devices.

One of the biggest advantages of silicon steel is its ability to significantly reduce energy losses in electrical equipment. Its high electrical resistivity lowers eddy current losses, which are currents induced in the steel that waste energy as heat. Additionally, silicon steel’s low hysteresis loss means less energy is lost during the magnetization and demagnetization cycles that occur in transformers, motors, and generators.

By minimizing these core losses, silicon steel helps electrical devices operate more efficiently, reducing electricity consumption and heat generation. This efficiency is especially important in power transformers and motors used in industrial and commercial settings, where even small efficiency gains translate to substantial energy savings over time.

Silicon steel is cost-effective for several reasons. Its efficiency reduces operating costs by lowering energy consumption. Moreover, improved magnetic properties allow for smaller and lighter cores, which decreases material usage and manufacturing expenses.

The durability of silicon steel also contributes to cost savings. Its resistance to wear and fatigue means devices last longer, reducing maintenance and replacement costs. The ability to produce silicon steel in thin laminations further cuts costs by reducing eddy current losses without significantly increasing manufacturing complexity.

Overall, silicon steel provides a strong return on investment by balancing upfront material costs with long-term operational savings.

Durability is another major benefit of silicon steel. The addition of silicon strengthens the steel, making it more resistant to mechanical wear and fatigue caused by continuous magnetic cycling. This toughness ensures that electrical devices maintain their performance over extended periods, even under demanding operating conditions.

Silicon steel laminations also resist cracking and deformation during manufacturing processes like stamping or cutting. This mechanical resilience is vital for maintaining the integrity and magnetic performance of cores in transformers, motors, and generators.

Furthermore, silicon steel’s stability at elevated temperatures helps electrical machines withstand heat generated during operation without degrading magnetic properties.

Tip: To maximize energy efficiency and durability in electrical devices, always choose silicon steel grades with optimized silicon content and lamination thickness tailored to your application’s operating frequency and mechanical demands.

Producing silicon steel involves precise control over its composition and processing to achieve optimal magnetic and mechanical properties. One major challenge is maintaining uniform silicon content throughout the steel. Variations can cause inconsistencies in magnetic performance and mechanical strength.

The manufacturing process requires careful rolling and annealing steps. Grain-oriented silicon steel demands exact heat treatments to develop the desired grain alignment. Any deviation can reduce magnetic efficiency or increase brittleness. Additionally, silicon steel tends to become brittle as silicon content rises, making it harder to handle during stamping or cutting. This brittleness can cause cracks or fractures in thin laminations, increasing scrap rates and production costs.

Coating the silicon steel laminations with insulating layers is another critical step. The coatings must be uniform and durable to prevent electrical shorts between layers, which otherwise increase eddy current losses. Applying these coatings consistently at high volume can be complex and costly.

Silicon steel performs well at power frequencies (50-60 Hz), but its effectiveness declines at higher frequencies. At elevated frequencies, eddy current losses increase despite the steel’s high resistivity and thin laminations. These losses cause more heat generation, reducing efficiency and potentially damaging components.

The steel’s magnetic permeability also drops at high frequencies, limiting its ability to channel magnetic flux effectively. This restricts silicon steel’s use in applications like radio-frequency transformers or inductors, where frequencies can reach kilohertz or megahertz ranges.

Moreover, the mechanical brittleness of silicon steel laminations becomes more problematic in high-frequency devices that require very thin sheets. Thinner laminations help reduce eddy currents but are more prone to cracking and handling damage, complicating manufacturing and assembly.

For these reasons, alternative materials such as amorphous metals or specialized ferrites may be preferred in high-frequency electrical engineering applications. These materials offer lower core losses and better mechanical flexibility at high frequencies but may come at higher cost or with other trade-offs.

Tip: To overcome manufacturing challenges, invest in precise process control and quality inspection for silicon steel production; for high-frequency uses, consider material alternatives or hybrid designs to optimize performance and durability.

Silicon steel continues to evolve as researchers and manufacturers seek to enhance its performance for electrical engineering. One key innovation involves improving grain orientation techniques. Advanced heat treatment and rolling processes now produce silicon steel with even more precise grain alignment, reducing core losses further and boosting efficiency in transformers.

Another development is the creation of ultra-thin silicon steel laminations. Thinner sheets help cut down eddy current losses, especially important as devices operate at higher frequencies. However, making thinner laminations without increasing brittleness is challenging. New alloy formulations and processing methods aim to maintain mechanical strength while achieving reduced thickness.

Researchers also explore adding small amounts of other elements like aluminum or cobalt to silicon steel. These additions can improve magnetic properties or thermal stability, enabling silicon steel to perform better in harsh or high-temperature environments.

Coating technologies are advancing too. Modern insulating coatings on silicon steel laminations improve electrical insulation and reduce losses. These coatings are becoming more durable, heat resistant, and environmentally friendly, supporting longer lifespans and sustainable manufacturing.

Future electrical devices will demand materials that deliver high efficiency, compact size, and reliability. Silicon steel innovations will play a crucial role in meeting these needs.

For transformers, improved grain-oriented silicon steel will enable smaller, lighter units with less energy loss. This is vital for smart grids and renewable energy systems where efficiency and space are priorities.

In motors and generators, enhanced non-oriented silicon steel will support higher power densities and quieter operation. Electric vehicles and industrial automation will benefit from these improvements, leading to better performance and reduced energy consumption.

Emerging technologies like high-speed trains, aerospace electric systems, and advanced robotics will also rely on silicon steel’s magnetic and mechanical properties. As operating frequencies rise, new silicon steel grades designed for high-frequency applications may emerge, bridging the gap between traditional silicon steel and alternative magnetic materials.

Overall, silicon steel’s ongoing development promises to support the electrification and digital transformation of industries by providing more efficient, durable, and cost-effective magnetic cores.

Tip: Stay updated on silicon steel innovations and collaborate with suppliers to select advanced materials that optimize efficiency and durability for next-generation electrical devices.

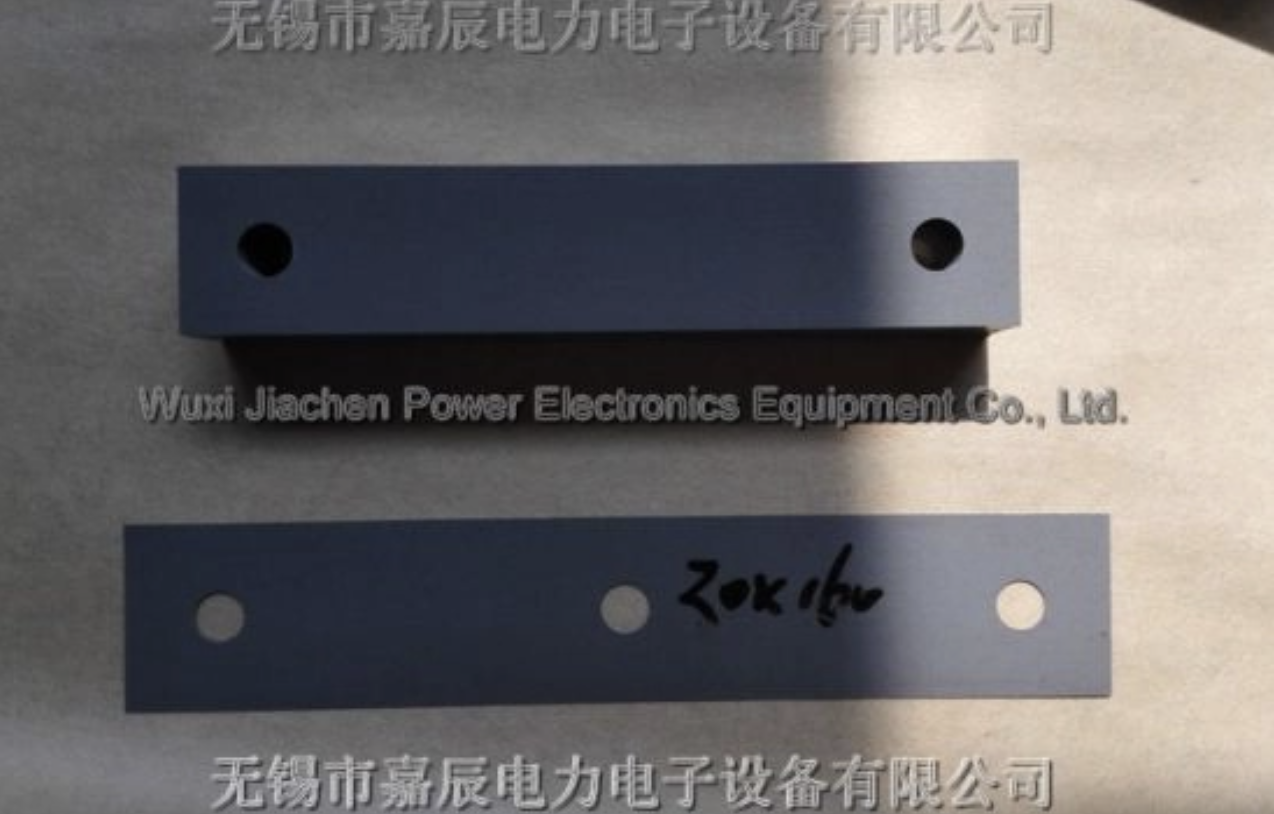

Silicon steel, essential in electrical engineering, optimizes magnetic and electrical properties in transformers, motors, and generators. Its energy efficiency and durability enhance device performance and longevity. Future advancements will improve grain orientation and lamination thickness, supporting high-frequency applications. As industries evolve, silicon steel will remain vital in meeting efficiency and reliability demands. Wuxi Jiachen Power Electronics Equipment Co., Ltd. offers cutting-edge silicon steel products, ensuring superior magnetic cores that drive innovation in electrical engineering. Their products provide unmatched value, supporting next-generation electrical devices.

A: Silicon steel is used in electrical engineering for its excellent magnetic properties, making it ideal for transformer cores, motors, and generators.

A: Silicon steel improves energy efficiency by reducing core losses through its high electrical resistivity, which minimizes eddy current losses and heat generation.

A: Grain-oriented silicon steel is preferred for transformers due to its aligned crystal grains, which enhance magnetic flux flow and reduce core losses.

A: Non-oriented silicon steel offers balanced magnetic performance in all directions, reducing core losses and improving efficiency in rotating machines like motors.

A: Silicon steel is cost-effective due to its efficiency, durability, and reduced material usage, offering a strong return on investment compared to other materials.